The article discusses the increasing demand for high-quality, customized specialty steels across various industries such as automotive, aerospace, defense, healthcare, energy, and electronics. It highlights the importance of technological advancements in steel production, including Ladle Metallurgy and Continuous Casting, which improve efficiency, reduce environmental impact, and meet specific industry needs. The global special steel market size, growth trends, and adoption of these technologies are explored, along with government initiatives and market dynamics. The article emphasizes the significance of advanced technologies for the competitiveness and sustainability of steel manufacturers in the evolving industry.

As the human race pushes the boundaries of the known and explores the unknown, we are in constant need of the best tools to achieve the impossible. We need tools that are made from materials of the best quality. The need for higher quality and customized materials has been growing.

Steel is an important commodity in the global markets and has widespread applications. In the realm of modern steel production, technological advancements have played a pivotal role in enhancing efficiency, quality, and cost-effectiveness. The techniques have not only improved the metallurgical properties of steel but also revolutionized the manufacturing process, leading to increased productivity and reduced environmental impact.

Globally, the demand for high-quality steel products with customized properties has been witnessing growth owing to the specialized needs for materials across sectors. The Automotive industry is a major consumer of specialty steel. The Aerospace and Defence sector has stringent requirements for materials used in aircraft, missiles, and defence systems. Similarly, specialty steels find applications in the Medical and healthcare sectors for the manufacturing of surgical equipment, implants, and other medical devices. Furthermore, there is a growing need for specialty steels in the Energy sector, Tool & Die industry, Infrastructure development, and Consumer Electronics. Additionally, the need for sustainable and energy-efficient manufacturing processes led to companies adopting Ladle Metallurgy and Continuous Casting for producing specialty steels.

Ladle Metallurgy, also known as secondary steelmaking, is the process of refining molten steel after it is tapped from the primary steelmaking furnace. Ladle metallurgy helps remove impurities and adjust the composition of the steel to meet customers’ demands.

Continuous Casting is a technique that allows for direct production of semi-finished steel products. It eliminates the need for ingot production and subsequent reheating.

The key indicator of penetration and adoption of Ladle Metallurgy and Continuous Casting is the volume of demand for specialty steels across industries. Ladle Metallurgy is often a necessary step in the manufacturing of specialty steels.

According to a research study by the Business Research Group, the global special steel market size grew from $175B in 2022 to $188B in 2023. It is expected to grow at a cagr of 7.3% till 2027. Government of India in October of 2021, recognizing the potential and global demand for specialty steels, has approved a PLI scheme for manufacturing specialty steels in India with a financial outlay of ~$860 million over a five-year period. The scheme is expected to attract investments worth ~$5.4 billion and expand the specialty steel capacity by 25 million tonnes.

The performance of the Ladle refining furnaces is another key indicator of penetration of Ladle metallurgy and the growth in sales of the furnaces signal the pace of adoption by the industry.

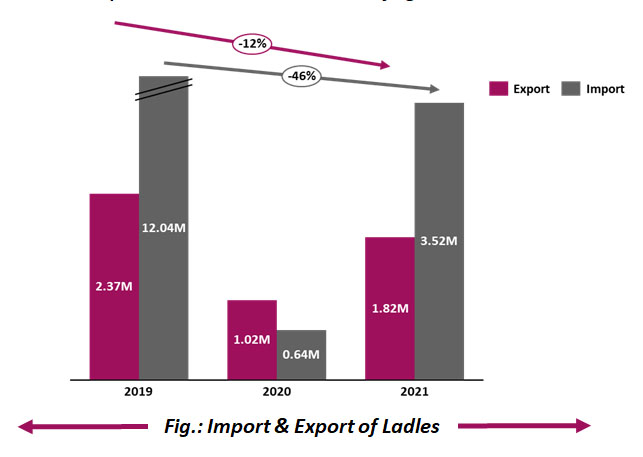

In the year 2021, India imported Ladles worth USD 3.5 million and exported USD 1.8 million in total. However, the numbers are significantly lower than the trade that had taken place pre-pandemic. The covid-19 pandemic followed by the Russia-Ukraine war has had a significant impact on this market. The supply chain disruptions have hampered the economic activity of major players. As the world recovers from these disruptions, the market is expected to experience slow but steady growth in the near future.

*Source: ITC TradeMap

These macroeconomic events can be considered a temporary aberration in the rapid growth of the ladle refining furnace market and the pace of growth is expected to return to normality.

According to MarketWatch, the global Ladle Refining Furnace market is expected to witness an accelerated growth of 13.7% between 2023 & 2030. The market is experiencing growth in the North America, APAC, Europe, and China markets. APAC in particular is expected to drive the growth of the market owing to the need for fast-paced infrastructure development and construction activities.

In addition to Ladle Metallurgy and Continuous casting being utilized for the manufacturing of refined steels, they minimize the operational costs of manufacturing by reducing the need for downstream processing and costly secondary treatments. This makes the overall steel production process more effective. Continuous casting, on the other hand, enables the production of wide-ranged semi-finished products with precise dimensions and consistent quality. This enables the companies to cater to diverse customer demands and optimize product mix, enhancing market competitiveness. The elimination of ingots and subsequent reheating also reduces energy consumption and increases productivity for companies.

As the steel industry continues to evolve, the adoption and integration of advanced technologies will be paramount for companies striving to remain competitive in the global marketplace. The financial benefits derived from these innovations will propel the growth and sustainability of steel manufacturers in the future.

Harsha Kamepalli

Harsha Kamepalli is a strategy consultant with experience in performance improvement, commercial planning, bid management and reporting. He is also a graduate from SIBM Pune specialising in Operations and Supply Chain Management. He enjoys long drives and exploring different cuisines of food in his free time.